Supplier Scenario

Note

Scenario Navigator Overview section in How to Use the Application introduces the purpose and benefits of scenario functionality.

Structure Overview section details the hierarchy from individual Scenarios to Network Scenarios and Batch Runs.

Scenario Pages Layout section describes the shared functionality that is common across all types of scenarios.

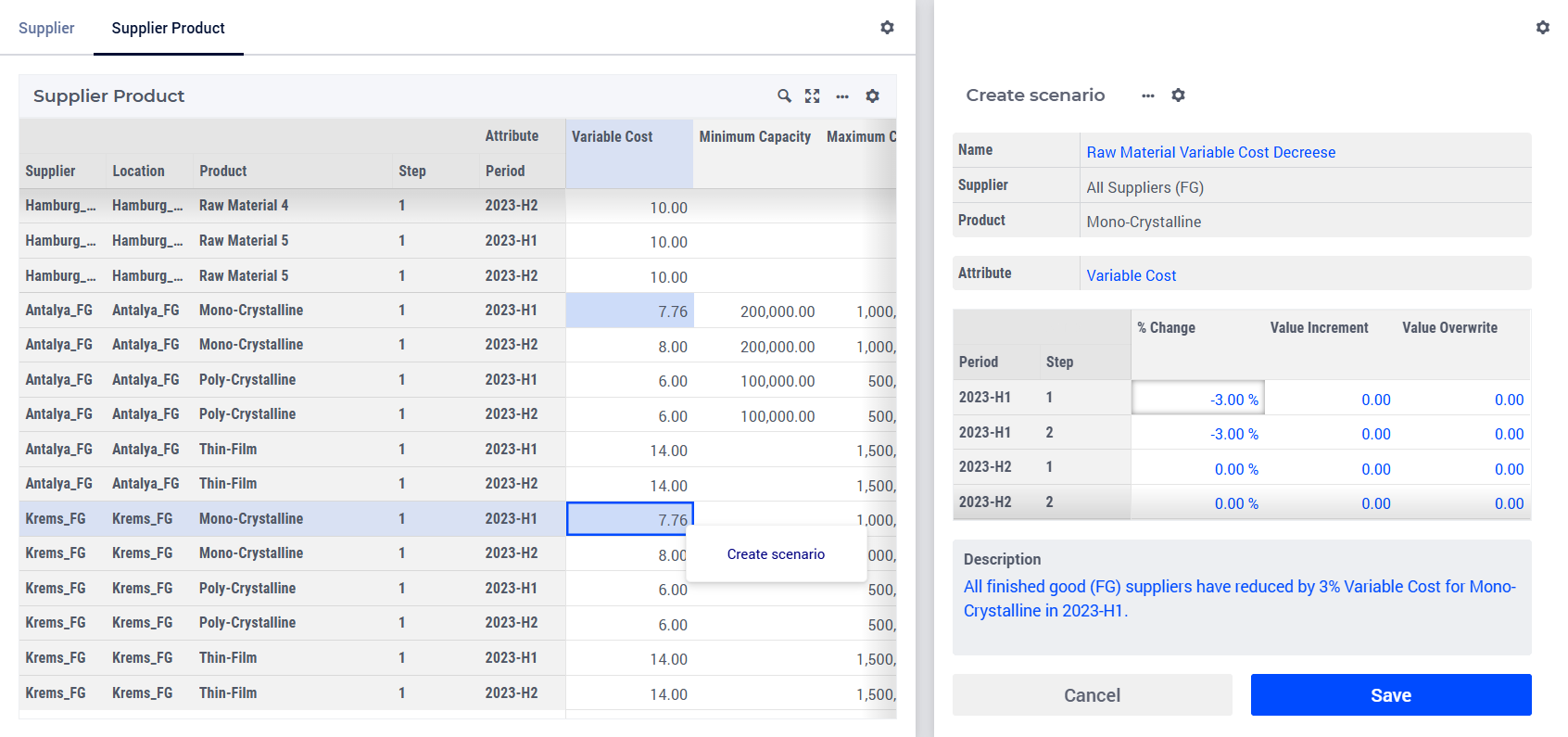

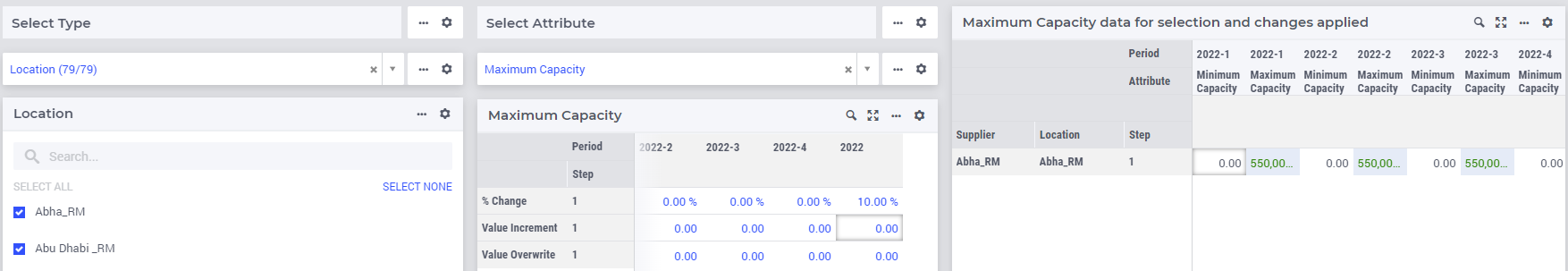

On this page, you can create Scenarios for the supplier input data. A Supplier Scenario is an adjustment of the data of an Attribute in one of the Supplier data tables. There are two different types of Supplier Scenarios: Supplier and Supplier Product. In the Data Tabs area, there are two tabs corresponding with the two types of Supplier Scenario:

Supplier Data Tab displays data in Supplier, Location, Step, Period

Supplier Product Data Tab displays data in Supplier, Location, Product, Step, Period

Examples

Scenario 1: One supplier has increased its ‘Maximum Capacity’ by 10% in all locations and all periods for step 1.

Supplier ‘Antalya_FG’ has increased its capacity in all locations and all periods.Select Supplier to be ‘Antalya_FG’. For Location leave it empty.

Select the ‘Maximum Capacity’ Attribute from the drop-down list.

In the table underneath, enter the value 10 in the cell at the intersection of the column ‘% Change’ and the row for the period group ‘2023-CY’ and step ‘1’.

Scenario 2: The Suppliers in a group of locations decrease cost.

All finished goods (FG) suppliers have reduced by 3% ‘Variable Cost’ for ‘Mono-Crystalline’ in ‘2023-H1’.Select Location to be the group ‘FG’ (by default, all Suppliers will be selected, there is no need to select any).

Select Product to be ‘Mono-Crystalline’.

Select the ‘Variable Cost’ Attribute from the drop-down list.

In the table underneath, enter the value -3 in the cell at the intersection of the column ‘% Change’ and the rows for the period ‘2023-H1’ and steps ‘1’ and ‘2’.